Pomati

Chocolate processing equipments

On both the Italian and international market since 1967, Pomati Group srl offers machines and accessories for chocolate processing in a variety of industry related niches: pastry shops, ice cream parlors, catering, bread making, as well as small- and medium-size confectionery factories.

Pomati blend the experience honed over time with modern technology in order to give life to ever so reliable, state-of-the art products of exceptional quality.

In addition to offering technological advanced products, Pomati’s also provides pre- and post-sale consulting services, and professional development courses delivered by the Dado Chocolate School.

Pomati product range

Pomati dedicates a great attention to detail in the designing phase yields a series of innovative elements introduced into the entire range of tempering machines. Removal of the auger permits a rapid change of chocolate product, as well as easy cleaning operations. Direct-gas cooling yields exceptional chocolate fluidity, even for extended processing times. Heating of the food-grade diathermic oil tank evenly distributes and maintains heat on the chocolate, while also ensuring reduced energy consumption.

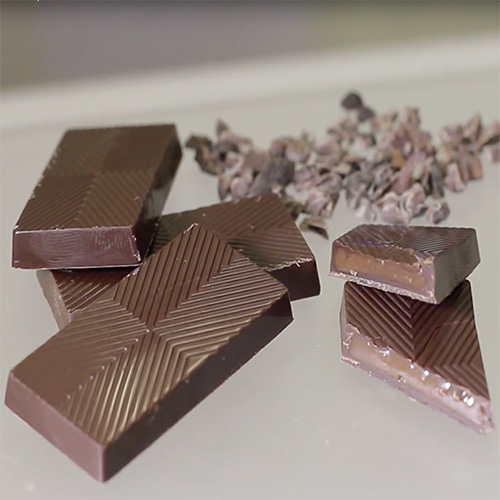

Tempering and melting machines: to melt and temper any type of chocolate. Direct auger tempering allows chocolate fluidity and a perfect crystal blend, thus an end product of exceptional quality.

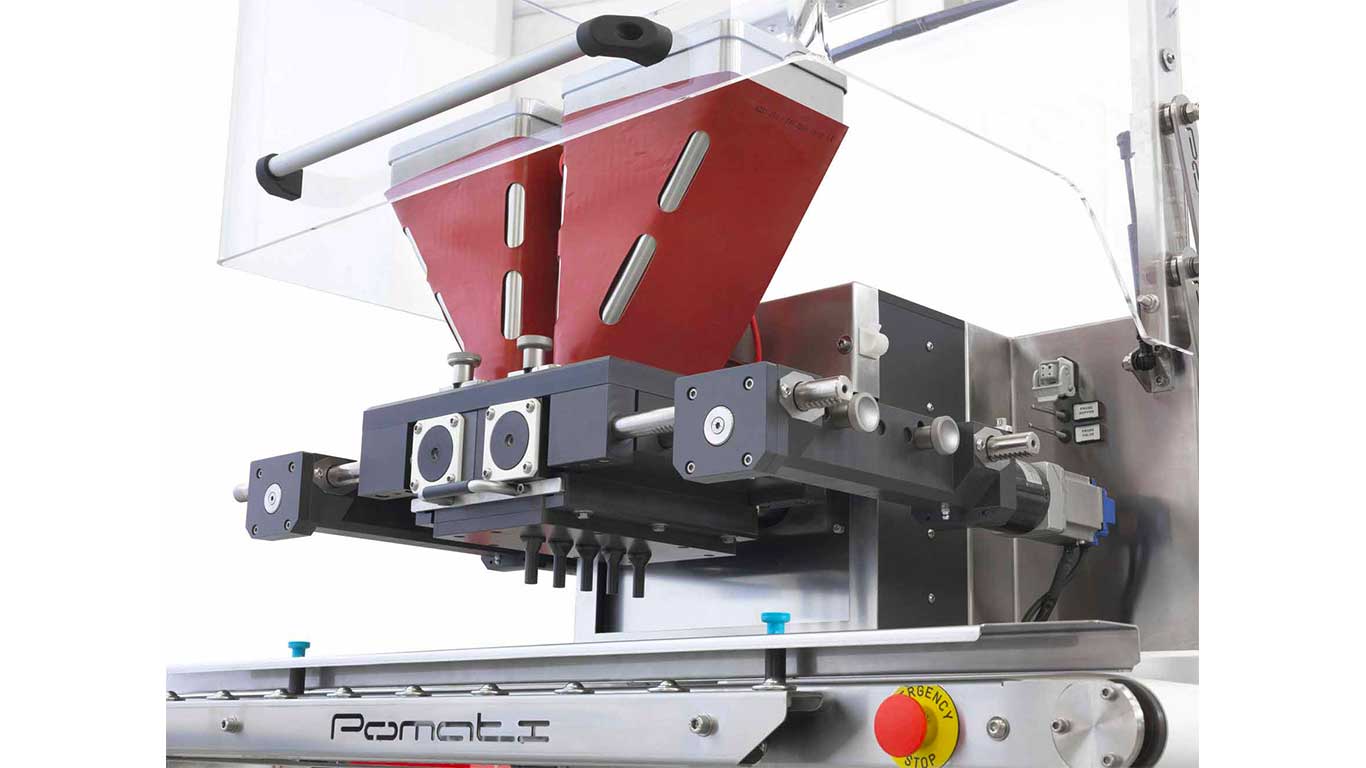

One Shot depositor: Pomati’s real revolution, to produce up to 140 kg. of chocolates per hour. The machines are suitable to produce pralines, truffles, filled chocolates, chocolate bars and any other seasonal products that cannot be hand-made.

- Vertical cooling tunnel: the first Pomati tunnel in a vertical version that in only 2m of width cools as much as a 20m tunnel, with 90% savings on the overall dimensions. Thanks to its innovative, patented cooling system, Verticale 175 can cool 72 molds at the same time, with reduced energy consumption. The system boasts a high reliability thanks to its servocontrols and its large versatility, and can be used in automatic, semiautomatic or manual mode. Verticale 175 can be adjusted to current production lines, reducing their extension and increasing their performance

- Cooling tunnel: expressly designed and built to cool products like chocolate Easter eggs, cookies, and covered sweets,it is ideal for both artisanal and industrial factories. The warm product is delivered to the tunnel by a conveyor belt, where it is cooled by low-temperature forced air. The refrigeration system and the belt’s conveyor are activated by manually handling the control panel.

- Carousel for hollow bodies: controlled by a foot-pedaled device, seems to be able to perform magic. Magnetic plates keep molds in place, thus ensuring that production is completely trouble-free. The carousel allows the movement of Easter and Christmas chocolate items weighing up to 3 kg.

- Large set of accessories for the previously mentioned equipment

Fields of Application