INOX-FER

Food Processing Machines for Convenience Food, Dairy, Confectionery

INOX-FER is an italian company that from nearly half a century designs and manufactures equipment for the food and beverage industry. Founded as a manufacture of machines for mixing and producing beverages, spirits and brines today INOX-FER it’s one of the leaders in the construction of complete processing lines for fruit and vegetables. His technology is used to produce fruit juices, sauces, jams, gravies and ketchup to name a few. Experienced staff, advanced technology and important trade relationships are at the basis of the success in Italy and around the world.

INOX-FER strong values have always been the willingness to understand and listen to the production needs of each individual client, producing feasibility studies and ad hoc projects based on the level of automation, the production capacity and the final product to be obtained. INOX-FER customers can rely on our exceptional after sales services made of qualified personnel ready to intervene and resolve any situation that may occur.

INOX-FER product range

Thanks to over thirty years of experience in the field of food processing machines Inox Fer offers a wide range of solutions ranging from the single mixing machine to a complete processing line.

The Research & Development division is constantly studying and selecting new materials and technologies both in the design and production process that will allow us to create better performing machines with lower energy consumption and lower acoustic emissions.

- Jams & sauces production line

- Fruit & tomato processing line

- Ketchup production line

- Nectars production line

- ProCut vacuum cutter for industrial production of pesto, salsa, sauces in a single cycle

- Mixing and storage: mixers, dissolvers, tanks

- Processing: under vacuum candying, defreezers & heaters, blanchers, cooking tanks, concentration and cooking boules, horizontal resting tanks, sterilizers, pasteurizers & tubular heat exchangers

- Transport: lifting and tilting machines, trolleys, swing loaders, belt conveyors, screw conveyors

Fields of Application

ProMix Mixers

Inox-Fer ProMix mixers dissolve perfectly multiple types of additives, starting from a low viscosity to products that are highly difficult to dissolve.

The liquid is recirculating while the solids are manually or automatically added through the hopper.

Several preparation tanks can be connected to the mixer.

ProMix is designed for the dissolution of solids in the applications of the food-processing, pharmaceutical and chemical industries. Dissolution of sugar for the beverage production, milk reconstitution, syrup production, brine preparation, milk product premixtures and ice-cream production are some of its applications.

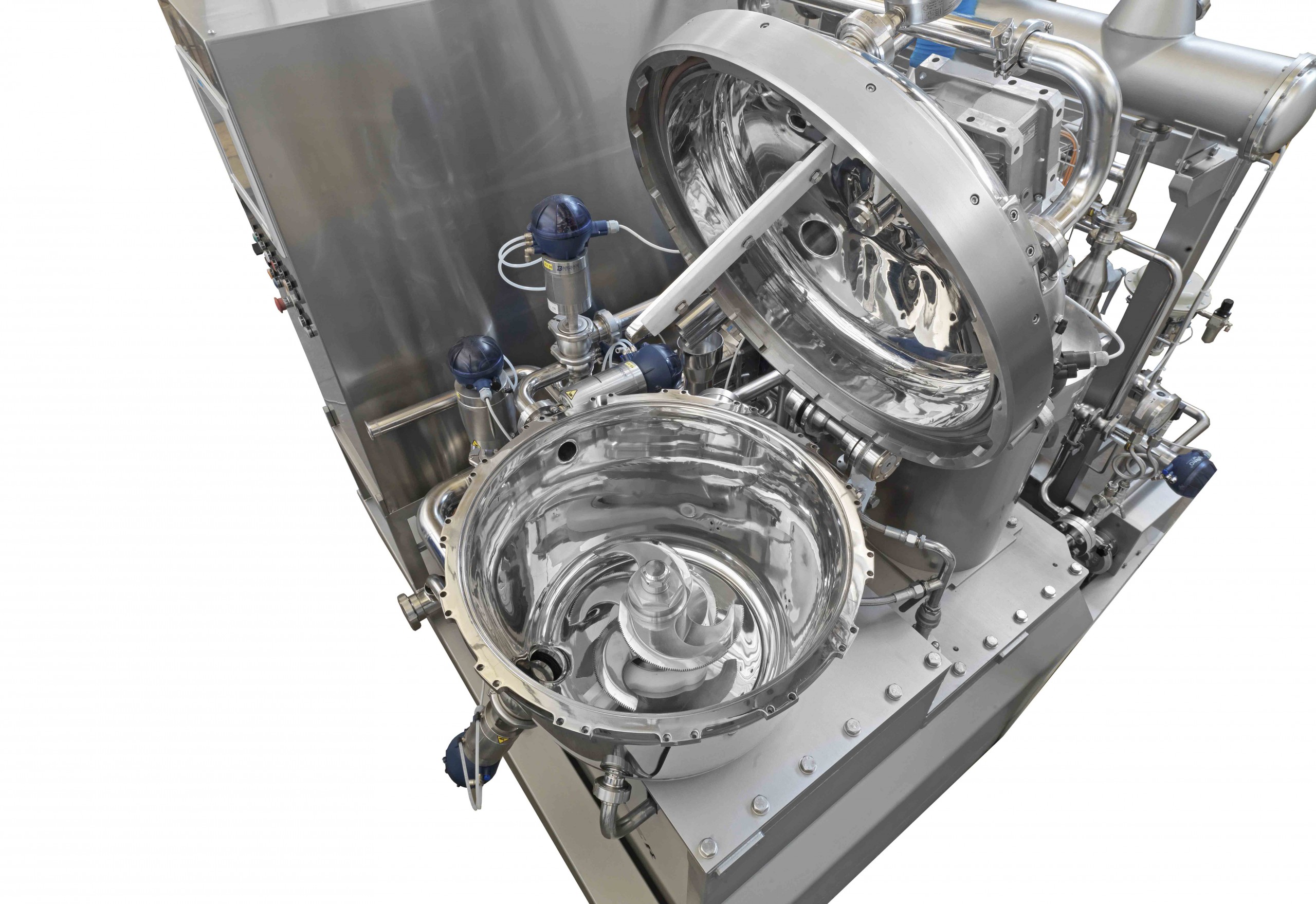

ProCut industrial cooking mixers

The ProCut industrial food cutter has been designed with the purpose of obtaining a finished product, starting directly from the raw materials and using a single piece of equipment in a single work cycle.

As a matter of fact, with ProCut you can, starting from raw materials, cut, mix, cook at temperatures as high as 120°c or under vacuum, homogenize, concentrate and cool the desired product in a single working cycle before it is sent directly to the filling phase.

Thanks to its versatility ProCut finds applications in many different industries such as sauces & ready melas, confectionery and dairy.

Vacuum concentration system

Vacuum concentration system is the best solution in the production of products such as jam, marmalades, sauces and seasonings.

The vacuum processing allows to concentrate, cook and de-aerate the product at lower temperatures ensuring a final product of excellent quality able to preserve its original organoleptic properties.